Understanding Brake Judder

18 Feb 2025

Category:

Brake judder is a vibration that can be felt through the steering wheel, the brake pedal, or sometimes the driver’s seat. With severe judder, you may even feel the car shake. It can be an uncomfortable and disconcerting experience, and a driver may reduce their braking pressure to reduce their discomfort, consequently increasing their stopping distances.

When this occurs, drivers and mechanics often assume that the brake discs have warped. To truly understand brake judder and diagnose the causes, we need to break it down into immediate brake judder or brake judder that has developed over time.

Immediate Brake Judder

In instances where brake judder occurs immediately after fitting a new set of brake discs, you may be inclined to think that the discs have been manufactured incorrectly. However, all NAPA Brake Discs are made to exact OE specifications and rigorously tested before leaving the factory to avoid this exact scenario.

Immediate brake judder will only be a result of an undiagnosed mechanical issue, such as:

- A severely worn or damaged hub, hub flange, and/or wheel bearing.

- Severely worn or loose steering and suspension components.

- Loose wheel bolts.

- Incorrectly seated wheel/discs.

- Damaged tyres.

- Buckled rims.

- ABS fault.

- Loose brake components (i.e. carrier).

This list is not exhaustive. If these underlying issues are not resolved, the brake judder will persist, and it could even lead to catastrophic mechanical failure.

Developed Brake Judder

Immediate brake judder is uncommon. Most often, brake judder will develop over time. Again, you may instinctively want to assume that the brake discs have warped from the high temperatures caused by braking.

Due to modern materials and manufacturing processes, however, it is extremely rare for any brake disc for warp. There would need to be a combination of extreme conditions for warping to occur, such as glowing hot discs being driven through standing water, or excessive overheating with insufficient cooling.

The most common cause of brake judder is a brake disc that has developed Disc Thickness Variation (DTV) over time.

What is Disc Thickness Variation (DTV)?

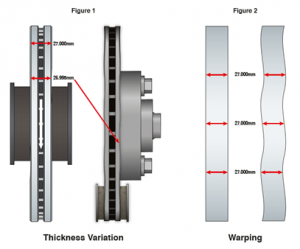

Disc Thickness Variation occurs when the brake disc has worn unevenly, causing the two friction surfaces of the disc to no longer be parallel with each other (see Figure 1).

This is often confused with disc warping, but they’re distinctly different problems. Warping is defined as distortion, where the disc is a uniform thickness and it’s the entire structure of the disc that’s uneven (see Figure 2).

If no real diagnosis is performed except a test drive, and warped discs are assumed to be the cause, a replacement will only cure the issue for the next 2,000–5,000 miles until the juddering returns.

Disc Thickness Variation is a condition that develops over time, and the primary cause is uneven material transfer.

What is Material Transfer?

During the bedding-in process and subsequent braking applications, brake pad friction material must transfer evenly onto the surface of the brake disc. Please see our ‘Material Transfer Process’ article for details.

Anything that could affect this process (such as heavy braking or a mechanical problem) will cause uneven material transfer, which starts the process of DTV.

Uneven friction material on the surface of the disc leads to the development of high spots, which will heat excessively in comparison to the rest of the disc. If these high spots exceed 650°C, the cast iron transforms into a harder substance called Cementite. The disc is now chemically composed of different materials of varying hardness, and the two materials will wear at a different rate.

This chemical process will lay the foundation for a vibration that will eventually lead to irreparable disc damage, although brake judder may not be felt for over 2,000–5,000 driven miles. This is why customers often return with complaints of brake judder months after the discs were originally installed.

Diagnosing DTV

With DTV, the disc surface will not have warped. When measured with a micrometre at (at least) 8 equal points around the disc, there will be a variation of thickness.

A disc thickness variation of >30μm (>0.03mm) will cause the brake pads to pulsate over the uneven surface, which in turn will make the pistons kick back over every high spot. Brake judder symptoms are the result.

To ensure that the new brake discs you’re fitting don’t already have DTV, all NAPA Brake Discs are tested before leaving the factory and will have a disc thickness variation of <13μm (<0.013mm).

Skimming DTV-inflicted discs will temporarily remove the high spots and judder, but the hard spots of cementite will remain under the surface. The high spots and judder will return after several thousand miles.

Lateral Runout

To avoid DTV, we want to avoid uneven material transfer, and the single biggest cause of uneven material transfer is lateral runout. Lateral runout is when the disc is no longer parallel to the hub surface and deviating from its true axis (see Figure 3).

What Causes Lateral Runout?

- Not following best practice.

- Microscopic particles of rust or debris caught between the disc face and hub (clean thoroughly!)

- Corrosion build-up after the new discs have been fitted, (i.e., from using copper grease or not replacing a missing disc location screw).

- A worn or damaged hub, hub flange, and/or wheel bearing.

- Worn steering and suspension components.

- Over-torquing of the disc location screw.

- Over-torquing of the wheel bolt.

- Low-quality refurbished alloy wheels (uneven paint thickness).

This list in not exhaustive.

Uneven material transfer can also be caused by:

- Not following best practice.

- The brake pads rubbing on the disc when not braking due to a sticking pad, slider bolt, or caliper.

- The brake pads not contacting the disc evenly when braking due to a sticking pad, slider bolt, or caliper.

- Failure to follow the correct bedding-in process.

- Sitting with the brake applied for long periods of time while stationary (also known as pad etching).

- Severe overheating of the discs.

Please see our ‘Material Transfer Process’ article for details.

What Else Can Cause Judder?

Static spots.

When a vehicle is parked for an extended period, especially in areas of high humidity and salt content (i.e., coastal towns), corrosion can build up between the disc and pad, adhering them to each other. The corrosion forms static spots, which will cause intense judder when braking. Severe corrosion could also damage the brake pads.

To free the brakes, twitch the vehicle by speedily releasing the clutch. There will be temporary brake judder while the corrosion is present on the disc surface. If the judder persists, the discs will need to be replaced.

Brake disc below the minimum thickness.

Compressive and centrifugal force is regularly applied to brake discs, which creates a force of traction. ‘Compressive strength’ describes a disc’s capacity to withstand clamp load from the brake pads. This capacity will decrease over time as a brake disc wears down.

Once it exceeds the material’s resilient limit, deformation begins as soon as the disc cools down. Cracks or warping will start to occur.

It’s crucial to replace brake discs when the surface thickness is less than the minimum thickness engraved on the outer disc diameter.

DRIVE YOUR BRAKING KNOW HOW

Do you have further queries? For in-person support, book a TechMate visit today! Contact the team on 01174 288090. All other technical support is available via our expert NAPA Technical Team on 03333 136597 or email [email protected].

Air Filter Fitment Guide - NFA1587

When installing a new air filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2253

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read MoreFuel Filter Fitment Guide - NFF2272

When installing a new fuel filter, it’s important to ensure correct fitment is followed. Keep...

Read More